What is a Wedge Wire Screen

Wedge wire is a welded steel structure primarily used for filtering, separating, and retaining media. Wedge wire screens feature continuous V-shaped grooves that provide a larger open area per square foot compared to traditional methods, resulting in improved efficiency at both the inlet and outlet.

Manufacturing Process

Wedge wire screens are created by resistance welding V-shaped wires onto supporting rods. Our wedge wire screens are manufactured from high-quality raw wire, which is then cut, shaped, processed, and cleaned. Wedge wire can be ordered as raw screening material or fabricated into finished products tailored to your application requirements. By precisely controlling the slot specifications, JX Filtration can offer customers highly accurate flow distribution and effective filtration of media, debris, and sediments.

Support rods that extend perpendicular to the wrap wire strengthen and maintain the correct design configuration of the screen, enabling it to withstand high pressure demands.

Forms

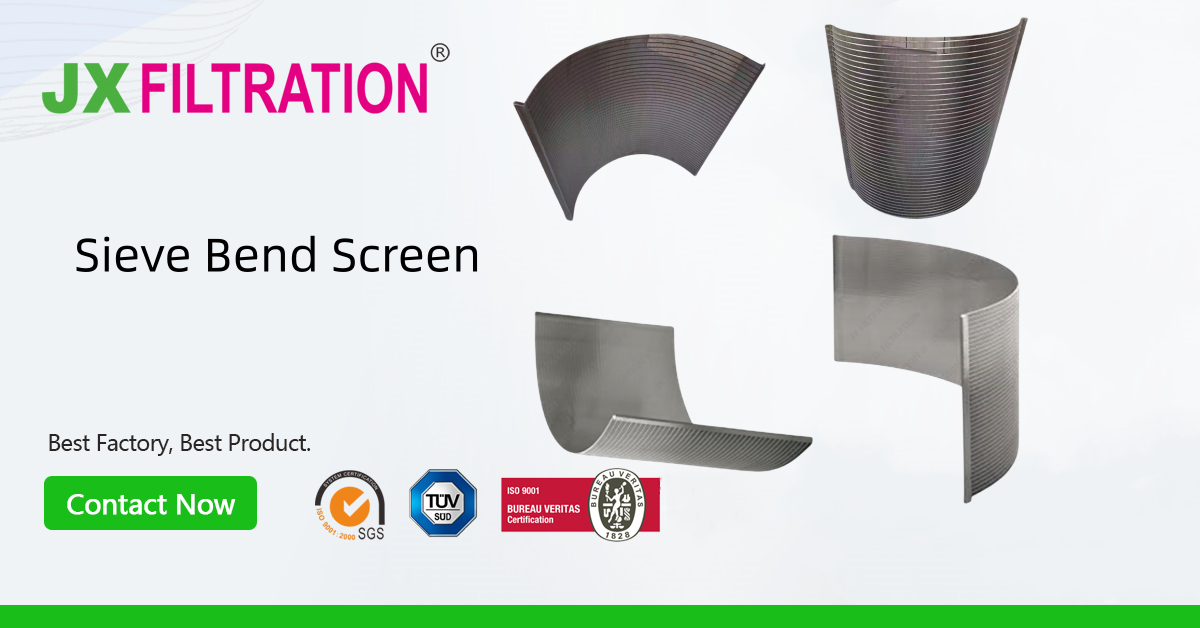

Screens can be manufactured in various forms, including cylindrical, flat, curved, or other shapes. The most common wedge wire filtration products include wedge wire filter panels, curved arc screens, wedge wire filter cylinders, screen tubes, stainless steel water caps, and wedge wire cloth distributors.

Applications

Wedge wire screens have become the preferred filtration element across various industries, including food processing, pulp and paper, mineral processing, oil and gas production, petrochemical refining, water and wastewater treatment, and drinking water supply.

Any Requirements, Contact Us Now!

Kris

Email/Teams: kris@filtrationchina.com

Mobile/Whatsapp/Wechat: +86 18980776200