Introduction to the Coanda Screen

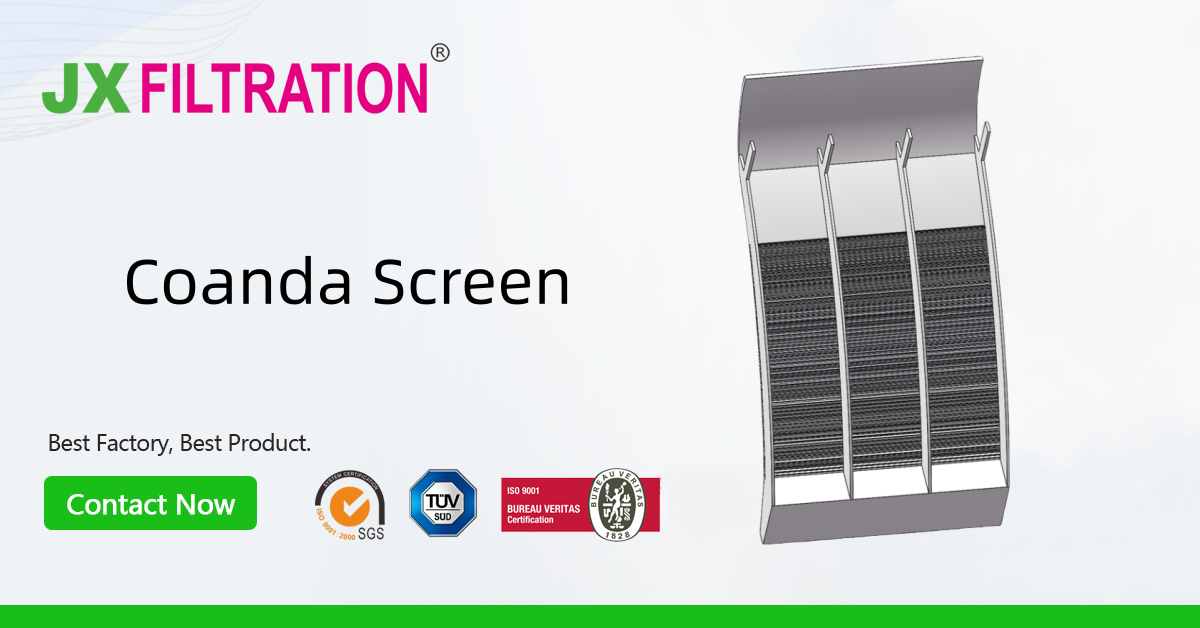

The Coanda Screen is a simple device capable of recovering fibers and particles from water suspensions. Its inclined screen structure is compact, with no moving parts, requiring minimal maintenance. The screen plates consist of an arc surface formed by wedge-shaped bars, with horizontal gaps between them, customizable based on customer requirements.

The liquid to be screened enters through the feed tank and, driven by gravity, flows towards the screen plate through a weir. As the suspension flows along the screen plate, a thin layer of water is separated from the bars, filtering out with fine particles through the gaps. Solid substances in the water are retained by the screen, rolling down along the arc-shaped screen under hydraulic and gravitational forces, eventually falling into the collecting hopper (optional).

I. Typical Application Industries:

- Papermaking wastewater – Recovery of fibers, removal of solid substances.

- Tannery wastewater – Removal of hair, grease, and other solid materials.

- Slaughterhouse wastewater – Removal of sacs, hair, grease, feces, and other solid materials.

II. Installation and Commissioning:

After suspending the Coanda Screen equipment and placing it on the foundation, secure it with anchor bolts. Connect the inlet and outlet pipes to the device. After filling with water, check the water flow, secure the adjusting bolts when normal, and the equipment is ready for operation.

III. Maintenance:

Regularly clean the screen surface with clean water to prevent the growth of biological films or clogging of the screen gaps, ensuring optimal performance.

If possible, install a high-level water tank at the inlet to reduce water flow velocity, achieve uniform water distribution, and enhance treatment efficiency.

IV. Precautions:

-

The liquid level behind the outlet of the Coanda Screen equipment must be lower than the equipment's outlet.

-

Avoid excessive lift for the sewage pump at the inlet.

Any Requirements, Contact Us Now!

Kris

Email/Teams: kris@filtrationchina.com

Mobile/Whatsapp/Wechat: +86 18980776200